- GST No. 33AAACH9339N1Z7

- Send SMS

- Send Email

Rubber Products

For more details please click on the links given below

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor |

| Material | Rubber,Custom |

| Shape | Round |

| Color | Black |

| Application | Industrial Use |

| Size | any size |

| Feature | Anti Viberating, Durable, Good Loading Capacity, Good Quality, Hiigh Strength, Perfect Shape |

| Load Capacity | 200-250kg, 50-100kg, Custom |

| Certificate | ISO 9001:2008 Certified |

| Type | Anti Vibration Mounting Pads |

| Country of Origin | India,India |

| Brand Name | Own Brand |

| Port | CHENNAI INDIA |

| Payment Terms | Other |

| Delivery Time | 2 WEEKS |

| Packaging Details | As per Standard International |

We can make any customized size and specification of Polymer and Metal Into Vibration Mounts to suit your needs .Contact us for more.Available NR Silicon EDPM Plastics FKM , and Metal as per requirement SS , Steel , Nickel Coated ChromE pLated

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Thickness | 3-80mm |

| Type | Bearings |

| Color | Available in Different Colors |

| Finishing | Coated |

| Features | Flexible, Highly Resistant, Durable |

| Why Us | Highly Durable Products, Competitive Pricing, Prompt Delivery |

| Material | Rubber |

Horiaki India Private Limited is Actively Engaged in the Manufacturing Supplying and Exporting of Rubber Bearings, Industrial Rubber Bearings Rubber Moulded & Extruded Parts and Rubber to Metal Bonded Parts Applicable for Use in Automobile and other Industries. Rubber Products, Rubber Molded Products, Rubber Profiles, Rubber Tubes, Rubber Gaskets, Orings and Bushes are Some of the Major Products that We Deliver. The Availability of Highly Skilled Professionals Holding Expertise in the Field Put Efforts to Raise the Standards of Products

A rubber bearing is defined as a device which permits constrained relative motion between two parts—rotation or linear movement. The fundamental purpose of a bearing is to reduce friction and wear between rotating parts which come in contact with one another in any kind of mechanism. Bearings are classified broadly into categories according to the motions they allow and according to their principle of operation. Each type of bearing is used for different purposes. Bearings are made of various materials but rubber is a widely demanded material for making bearings. Rubber has proved to be an excellent bearing material, especially under circumstances in which abrasives may be present in the lubricant. The rubber used to make bearings is a tough resilient compound similar in texture to that in an automobile tire. Apart from this main application, bearing devices must also allow –or prevent- relative movements (rotation and movement) of the joining elements, and have a durability according to the life of the structure they are placed in.

Among all different kinds of bearing, elastomeric bearings – in their different types- are the best known and most often used.

Types of rubber used in making bearings

- Natural Rubber

- Neoprene

- Butyl Rubber (IIR)

- Butadiene Rubber (BR)

- Ethylene Propylene Diene Monomer (EPM, EPDM)

Types of Rubber Bearings

Plain and Laminated elastomeric bearings: Bearings for construction industry in neoprene and natural rubber compound. Laminated rubber bearings provide the simplest method of isolation and are most suitable for high frequency ground motions.

High Damping Rubber Bearing (HDRB): This is ideal for seismic isolation. They are vertically stiff, capable of supporting vertical gravity loads, while being laterally flexible, capable of allowing large horizontal displacements. In effect, during an earthquake, the ground is allowed to move back and forth under a base isolated, while leaving the building to remain "stationary." These HDRB bearings are flexible and have energy absorption capability. The rubber bearings isolation system partly reflects and partly absorbs some of the earthquake input energy. Significant reductions of structural and non-structural damage can also be attained through the use of HDRB rubber bearings seismic isolation.

Low Damping rubber bearing: In the isolation system, the different types of rubber bearings are designed and used along with dampers. The system that is popularly adopted for buildings is the elastomeric or rubber bearings with low damping. These rubber bearings are widely acceptable because of their longevity, economy and better control on dynamic properties.

Lead Rubber Bearings (LRB): A lead rubber bearing is a much larger laminated bearing manufactured from layers of rubber which are sandwiched together with layers of steel and in the middle of the bearing there will be a solid lead "plug." Top and bottom of the LRB is fitted with steel plates, which are used to attach bearing to building through its foundation. Lead rubber bearings are designed in a way that the bearing is stiff and strong in vertical direction and flexible in horizontal direction. Lead, inserted as center of LRB dissipates the energy of earthquake and the rubber, reinforced with steel plates helps in providing stability, supports structure and isolates vibrations.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Available in Different Sizes |

| Material | Rubber |

| Shape | Round |

| Thickness | 1-5mm |

| Color | Black |

| Feature | Dustproof, Easy To Use |

Furthermore, the unique design of Rubber Bellows also exhibits as anti-vibration properties and noise reduction applications. The unique Rubber Bellows that we manufacture are mainly used in Automotive Control Cable industry, but other applications can be found within different industries, from power and cementation, to computer security. Available in variety of sizes, shapes, specifications and materials; this product has made us part of the elite group of Rubber Bellows Manufacturers.

The rubber molding tolerances for bellows and boots are complaint with rubber molding industry standard RMA A2 Precision tolerances.

Rubber bellows and boots are an essential part of many different industrial systems. They are flexible seals used in a range of applications for sealing dust and other environmental elements in applications with a calculated range of motion. Custom Gasket Mfg. fabricates rubber bellows and boots using one of three rubber molding methods; including compression molding, transfer molding and rubber injection molding utilizing the most recent rubber compounds available. Each of these methods has certain attributes that would be relevant based on the criteria of the application.

Rubber Bellows Structure:

Rubber Bellows can be engineered in a number of structures to meet various application requirements. The most common structure is composed of two connectors and a convolution region where the connectors provide the assembly interface and the convolution (bellows) region provides for the design application travel.

Our custom rubber bellows and boots are designed to protect against:

- Dust

- Water

- Oil

- Grease

- Acids

- Bleaches

- Spatter and pressure

- Moisturechemicals

- UV,other environmental elements

Convoluted Rubber Bellows and Boots

Convoluted rubber bellows and boots are versatile seals used in a broad range of industries and applications. These intricate seals can be custom designed allowing for a bellow or boot to have varying wall thicknesses and other configurations, not found in traditional styles. We can manufacture your bellow in a several durometers and in a variety of custom colors. Convoluted rubber bellows and boots are frequently used in many industries for applications including: steering components, pumps and cylinders and expansion joints for HVAC systems.

Custom Rubber Bellows and Boots in a wide variety of rubber materials and compounds including:

- Natural Rubber (NR)

- Silicone Rubber (VMQ)

- Neoprene®, Chloroprene (CR)

- Polyisoprene (IR, NR)

- Styrene-Butadiene (SBR)

- Butyl (IIR)

- Ethylene-Propylene (EPDM, EP)

- Nitrile, Buna-N (NBR)

- Fluorosilicone (FVMQ)

- Viton®, Fluorocarbon (FKM)

Applications and Usage

- Bellows are used in machine to prevent dust particles metallic chips machine to avoid damages.

- It gives longer life to the machine part to avoid breakdown of machine.

- Rubber bellows give better look to the machine and cover the damaged or unseen parts of the machine.

Horiaki, Manufacturer of rubber bellows offer the finest products made from complex set of raw materials.With its standard quality,it shines as the best suppliers and importers in Germany,UK,Europe.

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur

International Market

Saudi Arabia, Kuwait, Bahrain , Algeria, Kenya, Tunisia, Angola,Morocco, Senegal, Egypt,Nigeria, Uganda, Libya, Liberia, Swaziland , Switzerland,Vatican City, Iceland, Sweden, Russia, Germany, Poland, Austria, Romania, Spain, Portugal, Hungary, United Kingdom, Denmark,Norway, Netherlands, Italy, Greece etc

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Rubber |

| Shape | Round |

| Color | Black |

| Pattern | Plain |

| Features | Flexible, Highly Resistant , Durable |

| Why Us | Highly Durable Products , Competitive Pricing, Prompt Delivery |

Horiaki India Private Limited is Actively Engaged in the Manufacturing Supplying and Exporting of Rubber Bushes, Industrial Rubber Bushes, Coupling Rubber Bushes Rubber Moulded & Extruded Parts and Rubber to Metal Bonded Parts Applicable for Use in Automobile and other Industries. Rubber Products, Rubber Molded Products, Rubber Profiles, Rubber Tubes, Rubber Gaskets, Orings and Bushes are Some of the Major Products that We Deliver. the Availability of Highly Skilled Professionals Holding Expertise in the Field Put Efforts to Raise the Standards of Products. We manufacture Rubber Bushings of different shapes & sizes made from a variety of rubber grades like Neoprene, Nitrile, Silicone,polyurethane PU, EPDM, Viton, or Natural Rubber. We can also manufacture them according to customer’s specific requirements.

Rubber bushes are a type of anti vibration bush that generally consist of cylindrical inner and outer metals, fully bonded with rubber in between. The rubber bush for the suspension can be pressed into a housing, which will provide compliance between the inner and outer metals in the radial, axial , torsional and conical directions. A wide range of rubber bush designs can be offered; with hollow inner metals, solid inner metals (with lugs), segmented outer metals, and profiled inner/outer metals. If you require rubber bushes for a specific application, our experienced engineers can offer a custom anti vibration service using our advanced Finite Element Analysis software and calculations. We are the countries leading expert at creating bespoke anti-vibration fittings for a wide range of different industries.

Importance of Rubber Bushes:

The collection of automotive rubber bushes is designed with its end application in mind – to absorb the shock load axially, torsionally and radially. Also, the rubber bushings are used in various industrial applications. Some of the general terminology of the rubber bushings are anti-vibration mounting or flexible mounting. These products are used as vibration insulators in the automobiles. In this case, the synthetic rubber bushings or polyurethane rubber bushings are used for insulating steering, chassis and suspension components. This keeps out the factors of noise and vibrations from getting transferred to the vehicle's passenger cabin.

Types of Rubber Bushes:

Every type of rubber bush has a different set of properties for NVH (Noise, Vibration & Harshness).

Few of the popular rubber bushes types are as follows:

- Conical Bushes

- Equalizer Bushes

- Laminated Bushes

- Simple Bushes

- Flanged Bushes

- Pivot Bushes

- Spherical Bushes

- Suspension Bushes

- Torque Arm Bushes

- Void Bushes

Applications of Rubber Bushes in Automobiles:

- Attenuated noise transmission

- Elastic load bearing members

- Meeting the standards of low NVH (Noise, Vibration & Harshness)

- Vibration isolation

Why Us?

We manufacture Rubber Bushings of different shapes & sizes made from a variety of rubber grades like Neoprene, Nitrile, Silicone,polyurethane PU, EPDM, Viton, or Natural Rubber. We can also manufacture them according to customer’s specific requirements.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Rubber |

| Color | Black |

| Thicknesses Available | (Typically) 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm. |

| Sheet Size Available | (Typically) 1M x any multiple up to 10M |

| Features | Durable, Highly Efficient, Technical Configured |

| Why Us? | Quick Delivery, Technically Surround, Cost Effective |

We are a premium name in manufacturing Rubber Gaskets. Our widely selling Rubber Gaskets are manufactured using fine quality imported raw materials and latest technology. Our Rubber Gaskets is configured using the best quality of rubber available. Rubber Gaskets is available in a wide range of sizes and shapes. We manufacture our Rubber Gaskets, Industrial Rubber Gaskets according to customer’s design, dimension and polymer at very affordable price.

Rubber is the most important class of materials for sealing in the medium temperature range (-50 C to +120 C). This is because rubbers rapidly return to their original shape when any deforming stress or load is removed.

Many rubbers are available for various working conditions; however they all have one property in common – the effect of heat is cumulative and irreversible.

Maximum temperatures must not be exceeded and a good design will allow a safety margin dependent on design service life.

Many rubbers are available in foam (sponge) form for simple gasket sealing applications.

The Rubber sheet materials includes:

- White FDA Nitrile

- Hypalon®

- Butyl

- Red Rubber (SBR)

- Cloth Inserted Rubber

- Gum

- Diaphragm

- Silicone

- EPDM (Ethylene Propylene Dimonomer)

- Buna-N Nitrile

- Neoprene

- Fluroelastomer FKM

- FFKM

- Bridge Pads

- Coated Fabrics

Features :

- A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression.

- Gaskets allow for "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials.

- Common Gasket Uses

- One of the most common industrial uses of a gasket is acting as a seal for joining two water pipes. You can also find gaskets used to seal boilers and fuel tanks. In all cases the gasket prevents leakage of liquids and gases between the component parts.

Here are few of the common uses for gaskets and the types of gasket used:

- Sheet gaskets are ‘punched’ out of a sheet of material (usually a type of synthetic rubber) and are used to seal for pipes and tanks containing chemicals. The sheet gasket is ideal for use with acids, steam and corrosive chemicals.

- Ring gaskets are used mainly in off-shore oil and gas pipelines. They are solid rings of metal that operate under extremely high.

- Profile gaskets are both flexible and reliable in construction, which makes them highly suitable for use in older seals. These gaskets have a solid metal corrugated core with a flexible covering layer, allowing for high compression levels and a tight seal.

GASKET VS. SEAL: WHAT IS THE DIFFERENCE?

Gaskets

Gaskets are used when two flat surfaces of a component or flange are put together. The gasket is placed between the two and is there to prevent leakage. Basically, the gasket makes a static seal between two non-moving items. Whenever a piece of equipment is taken apart, a new gasket should be fitted.

Gaskets are manufactured from a variety of materials including Neoprene, Rubber, Nitrile, Viton, Graphite, Cork, EPDM and SBR. Cork and Graphite are used when the gasket is to be put under high rates of compression.

Gaskets are commonly used in the oil, gas, paper, automotive and electrical industries.

Seals

Seals are used to prevent leakages between two moving parts such as pumps, engine parts and shafts. A seal is generally round and flat, whereas a gasket will often be cut into a specific shape to fit the component it is to be fitted to.

Most seals are constructed of a metal outer ring with an inner rubber surface. This inner surface is tilted to create a lip, creating a second barrier against any drops of liquid that pass the first edge. A seal is often used to seal hydraulic lines and to prevent leakage from the end of a shaft.

INTERNATIONAL MARKET

- EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

- UNITED STATES(USA), CANADA, MEXICO

- RUSSIA

- AUSTRALIA AND NEW ZEALAND

- ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

- Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Usage | Automobile Parts |

| Specialities | Scratch Proof, Perfect Finish |

| Material | Rubber |

| Shape | Round |

| Color | Available in Different Colors |

| Is It Flexible | Yes |

Available in loose coil form or manufactured as hose assemblies with a full range of end connections; these Rubber Hoses conform to internationally prescribed quality norms and therefore is sure to meet customer’s expectations. Furthermore, the high tech mechanical setup at Horiaki also allows us to manufacture customized Rubber Hoses in terms of production material and design of the final product. We have very high regard for quality and therefore we test our product for any flaws and errors as far as quality or design flaws are concerned. The superior quality and impeccable finish of this product has helped us cement our place among the top Rubber Hose Manufacturers in India.

Materials :

- Natural Rubber, Isoprene (NR, IR)

- Styrene, Butadiene (SBR, BR)

- Butyl (IIR)

- EPDM, EPM

- Nitrile (NBR)

- Neoprene (CR)

- Hypalon (CSM)

- Silicone (SI, VMQ)

- Viton, Fluoroelastomer (FKM)

- Viton B Fluoroelastomer (FKM)

Superior quality and impeccable products are manufactured at Horiaki. It is the leading manufacturer, Suppliers and importers of rubber hose products in Germany, UK, Europe.

International Market

EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

UNITED STATES(USA), CANADA, MEXICO

RUSSIA

AUSTRALIA AND NEW ZEALAND

ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain. Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc.

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvananthpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Materials | NR=Natural Rubber(SMR) |

| Application Field | Water, Closed Loop Water Arrangements, Soluted Lyes at max 50% conc. and mx 80% |

| Color | Black |

| Hardness | DIN 53505, Shore A 60-80 +/-5 |

| Density | DIN 53479, g/cm3 1.384 |

| Temperature | Approx. +80°c, Short-term Up to +90°c |

| Certificates | Approval of own test facility. |

All our products including Rubber Gaskets are in compliance to world standrads like KTW , W270,DGVW, WRAS ETC are standardized and are only manufactured with SYNTHETIC Rubber SUCH AS EPDM, NBR, SILICON,FKM,FFKM having hardness of DIN 53505, Shore A to make them resistant to water, seawater, pond water, closed loop water up to 90°C and also against alkalines up to some extend like 50% NaOH at 50o.

For effective functioning at even high temperature range of approx. +80°C and for short-term up to +90°C, HoriakiIndia Pvt. Ltd. Rubber Metal Gaskets Water Lines, Rubber Metal Gasket DGVW etc. have the density DIN 53479, g/cm3 1.384.Based on our own test facilities Horiaki India Pvt. Ltd. manufactured rubber metal gaskets are certified resistant even against natural lighting, weather and ozone. Limited only by the natural properties of vulcanized rubber our rubber metal Gaskets are not resistant against fuel, mineral oils, acids and gases.

Chemical resistance :

- Vulcanisates of natural rubber (NR) are resistant against: water, seawater, pond water, closed loop water up to 90°C

- Partly against alkalines, 50% NaOH at 50°C

- Sufficient resistant against natural lighting, weather and ozone

- Vulcanisates of natural rubber (NR) are not resistant against:fuel, mineral oils, acids and gases

Application field : The application of NR-vulcanisates is possible where natural media have to be sealed. Temperatures higher than 90°C have to be avoided.

Function and durability : The performance and life of Horiaki gaskets depend in large measure on proper storage and fitting, factors beyond the manufactor’s control.We can, however, vouch for the excellent quality of our products.With this in mind, please also observe our installation instructions.

Rubber Metal Gaskets KTW

- The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring

- Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

- Vulcanised rubber gasket, cross section in lens form, rounded edges.

- Inside vulcanised steel ring, therefore good reception of the bolt force.

- Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

- Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

- DN 15 up to DN 2000

Rubber Metal Gaskets W270

- The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

- Sizes at the measurement table:

- d1 = Inner diameter

- d2 = Outer diameter

- s = Thickness

- Vulcanised rubber gasket, cross section in lens form, rounded edges.

- Inside vulcanised steel ring, therefore good reception of the bolt force.

- Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

- Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

- DN 15 TO 2000

Rubber Metal Gaskets- DGVW

- The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

- Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

Vulcanised rubber gasket, cross section in lens form, rounded edges.

- Inside vulcanised steel ring, therefore good reception of the bolt force.

- Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

- Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

- DN 15 TO 2000

Rubber Metal Gaskets water lines

- The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

- Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

- Vulcanised rubber gasket, cross section in lens form, rounded edges.

- Inside vulcanised steel ring, therefore good reception of the bolt force.

- Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

- Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

- DN 15 TO 2000

- Rubber-Metal-Gaskets – Safe sealing of gases and liquids

- Safe sealing of water, gas, air, acids, alkalis and hydrocarbons with low sealing forces at temperatures up to 200°C, depending on the elastomer type.

- Rubber-metal-gaskets are used where safe sealing of conventional up to special industrial media such as gases and liquids are required under usual installation conditions like temperatures, pressures and forces

- Suitable for all flange materials

- A flange connection has to be always treated as a coherent system, because the sealing functions is determined by the interaction of individual elements including flanges, gaskets and screws

HORIAKI HRS

- Rubber gasket, lenticular shape, rounded edges. Steel ring, chemically treated, no possibility to separate the elastomers from the steel core. Suitable for flanges made of metal.

- Self-centering with the same flange DN and PN appropriate tightening torques

- Self-limiting compression surface

- Rigid gasket, easy to install

- Soft surface in order to seal slightly damaged flange surfaces

- Blow-off proof n Materials :NR, NBR, EPDM, CSM, FKM

- Dimensions according to EN 1514-1 depending on DN: PN 6 to PN 40 DN 15 up to DN 2000

HORIAKI HRS/S

- Rubber gasket, Lenticular shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rounded edges. The spear tip provides higher safety at lowest contact pressures.. Suitable for installation between flanges made of metal and plastic

- Self-centering with the same flange DN and PN

- Minimum tightening torques and smaller than HRS (see diagram below)

- Materials of HORIAKI HRS/S : NBR, EPDM, FKM, EPDM fire resistant

- Dimensions according to EN 1514-1 depending on DN: PN 10 to PN 40 DN 15 up to DN 1000

HORIAKI HRS/TS

- Rubber gasket, flat shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rectangular outside diameter. The spear tip provides higher safety at lowest contact pressures.

- suitable for flanges made of plastics such as PE, PP, GRP, PVC

- Self-centering with the same flange DN and SDR

- Reduced dead space

- Tight, also at low tightening torques

- Materials of HORIAKI HRS/TS: NBR, EPDM, FKM

- Dimensions according to the valid European standards for plastic tubes made of PE, PP, PVC, PVDF and GRP (mainly SDR 11,17 and 33)

Materials of rubber-metal-gaskets

NR

- Field of application: Water ,Circuit water ,Diluted alkalis up to max. 50% and max. 80°C

- Temperature: approx. +80°C, short-term up to +90°C

- Colour: Black

- Certificates: EN 681 -1 WC Class 70

- Applications: NR vulcanized materials can be used where noncritical media have to be sealed. Higher temperatures than 90°C have to be avoided

NBR

- Field of application: Gas Media containing hydrocarbon Waste water Water

- Color: black

- Temperature: from -15°C to +100°C

- Certificates: DVGW Certificate acc. to EN 682 GBL, EN 681-1 WG Class 70, EN 682 GBL Class 70 ,TA-Luft (German Clean Air Act)

- Applications of NBR vulcanized materials result from the listed characteristics, such as resistance against aliphatic carbohydrates, mineral oils, greases fuels

Epdm

- Field of application: Drinking water, Waste water Process water

- Color: black

- Temperature: from -40°C to +110°C, short-term up to +130°C

- Certification:EN 681 -1 WAL/WCL Class 70 ,Elastomer Guideline (new KTW,) DVGW W270 ACS, WRAS (BS6920), FDA Certificate, TA-Luft (German Clean Air Act)

- Applications of EPDM vulcanized materials mainly result from the good resistance to chemicals. Furthermore, the EPDM quality has a good resistance against ozone and aging.

Csm

- Application in case of alkalis and acids in the chemical industry

- Color: black

- Temperature: from -10°C to +80°C

- Certification: TA-Luft (German Clean Air Act)

- Applications of CSM vulcanized materials can be found in the chemical industry, in chemical cleaning etc.

FKM(VITON)

- Application in case of higher temperatures (Viton is the brand name of DuPont ® for FKM) in the chemical industry

- COLOR: brown

- Temperature: from -20°C to +200°C

- Certification: TA-Luft (German Clean Air Act)

- Due to the good resistance against acids and alkalis, the main use is in the area of chemistry and their users.

HORIAKI HRS-ptfelon

- Rubber-Metal-Gasket with PTFE jacket

- Gasket material: EPDM ethylene-propylene-rubber developed in accordance with the main European drinking water requirements. Very good properties of resistance against ozon and ageing.

- Material for jacket: Virginal PTFE up to DN 900, modified PTFE from DN 1000

Dimensions:

- HRS: DN 15 up to DN 2000 acc. to EN 1514-1.

- HRS/TS: DN 16 up to DN 400 SDR 11 and 17

- Application field: Safe sealing of pipe systems where aggresive fluids are flowing. Specially suitable for coated flanges and plastic flanges in PE, PP, PVC and GRP. PTFE is quite against all fluid resistant

INTERNATIONAL MARKET

- EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

- UNITED STATES(USA), CANADA, MEXICO

- RUSSIA

- AUSTRALIA AND NEW ZEALAND

- ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

- Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Rubber |

| Thickness | 0-3mm |

| Application | Gas, Water |

| Color | Rubber |

| Hardness | Hard |

| Features | Abrasion Resistant Finish, Better Strength, Durable, High Quality Raw Material, High Temperature Resistance |

| Sizes Available | From 10 mm – 200 mm |

We offer a premium range of Rubber Tubes highly appreciated for durable finish, high efficiency and standards. Rubber Tubes are made using high quality raw material with latest technologies. Rubber Tubes are made using high quality raw material with latest technologies. Apart from this, Silicon, NBR, and Neoprene Tubes in size ranging from 10 mm – 200 mm are also available with us. We provide the facility of customization of wires on the basis of size, shape and diameter depending upon the varying requirements of the clients. These Rubber Tubes, Silicone Rubber Tube, Rubber Tubes are resistant to high temperature and thus are capable of rendering long.

What distinguishes rubber tubing from other types of tubing is its rubber-based construction. Rubbers are elastomers, materials which have high yield strengths which allow them to be stretched much farther than other materials without suffering permanent deformation. Rubbers are known for their flexibility, tear strength, resilience, and thermal stability up to certain temperatures. Rubber materials can be classified as either natural or synthetic.

Various types of materials we offer :

- Black neoprene rubber tubing

- Neoprene tube is identified by ID and Wall Thickness

- Black 60(+/- 5) Durometer Shore A

- Sold in full rolls of 100ft unless otherwise indicated

- Tensile: 800 psi

- Elongation: 300%

- Specific Gravity: 1.3

- Extruded to RMA Commercial tolerances

- Meets ASTM D2000 3 BC 607 A14 B14 F17

Viton fkm rubber tubing

- Viton® is the most specified Fluoroelastomer rubber for fuel system seals, hoses, o- rings, and gaskets as well as many other uses.

- Viton® has excellent temperature resistance (up to 400℉) and offers a wide range of fluid and chemical resistance to oils, lubricants, and fuels.

- Tubing Extrusions

- Viton® Tubing available in Durometers 60-90

Latex rubber tubing

- Amber latex rubber tube (also available in black)

- 35(+/- 5) Durometer

- Tensile: 3500 psi

- Elongation: 750%

- Specific Gravity: 0.95

Sponge rubber tubing for insulation

- This pipe insulation is a flexible elastomeric thermal insulation

- Black in color

- Supplied as unslit tubing

- In nominal wall thicknesses of 3/8in., 1/2in., 3/4in., and 1in.

- In popular sizes up to 6in. IPS

- The tubing is made of nitrile/pvc blend

- The expanded closed-cell structure of this makes it an efficient insulation

Uses

- It can be used to retard heat gain and control condensation drip from cold-water plumbing, chilled-water, and refrigeration lines

- It also efficiently reduces heat flow for hot-water plumbing, liquid-heating and dual-temperature piping

Nitrile foam rubber tubing

- Made from Nitrile rubber. This material strikes a good balance between cost and quality.

- EPDM foam tubing is available for high UV outdoor use.

- Foam tubes are available cut to length or by the foot.

- Many sizes are available in coils

- Meets or exceeds ASTM D1056 Type 2,Class A, Grade 3 Specifications

Non latex stretch rubber tubing- gooch tubing

- This tubing is the material used to make rubber bands

- Made of Synthetic Polyisoprene

- Wall thickness is .040 to .045"

- EPDM compound is also available

Silicone rubber transclucent tubing

- Color: White translucent

- Durometer: 55(+/- 5) shore A

- Temperature: -100 Deg F to +450 Deg F

Gum rubber tubing

- Cost-effective, Resilient, and Abrasion resistant

- It makes an excellent vacuum tubing in smaller sizes because of its tear resistance and memory

- Versatile and cold temperature resistant

- It is able to maintain a high coefficient of friction during most applications

INTERNATIONAL MARKET

- EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

- UNITED STATES(USA), CANADA, MEXICO

- RUSSIA

- AUSTRALIA AND NEW ZEALAND

- ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

- Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor |

| Material | Aluminium, Iron, Metal, Stainless Steel,as per spec |

| Surface Finishing | Polished, Power Coated, as per requirement |

| Shape | Rectangular, Round, Square, as per requirement |

| Color | Black, Grey, Metallic, Shiny Silver, as per requirement,As per spec |

| Application | Automobiles, Automotive Industry, Fittings, Machinery |

| Certification | ISO 9001:2008 Certified |

| Grade | ASTM |

| Feature | Accuracy Durable, Dimensional, Hardend & Temper, High Quality, High Tensile |

| Technics | Black Oxide, Hot Dip Galvanized, White Zinc Plated, Yellow Zinc Plated |

| Type | Sandwich Mount |

| Diameter | 30-40mm, 60-70mm, 70-80mm, as per spec |

| Thickness | 0-5mm, 10-15mm, 5-10mm, as per spec |

| Country of Origin | India,India |

| Port | CHENNAI INDIA |

| Delivery Time | 2 WEEKS |

| Packaging Details | As per International Standards |

Our Reinforced Sandwich Mounts Provide Stablity and Vibration Control.

Polymer and Metal can be customized to requirements and load capacity

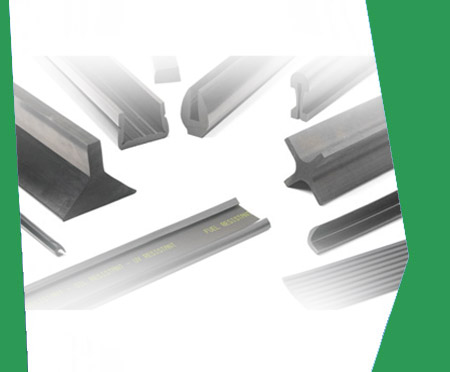

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Rubber |

| Application | Electrical Use |

| Color | Black |

| Features | Durable, Highly Upgraded Technology Used, Flexible |

| Why Us | Cost Effective, Surround Work Force, Prompt Delivery |

We are trusted firm, involved in manufacturing, exporting and supplying Adjustable Rubber Profiles in the global market. We have set-up a physical framework for manufacturing these profiles as per laid industry parameters. Further, our Adjustable Rubber Profiles can be personalized as per client’s requirements. One can attain them at marginal prices, from us.

Rubber profiles are available in continuous lengths and intricate profile shapes, but can be cut to length to meet our customer’s specifications. This adjustable rubber profiles are used in automobile industries, for industrial applications and construction industries.

INTERNATIONAL MARKET

- EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

- UNITED STATES(USA), CANADA, MEXICO

- RUSSIA

- AUSTRALIA AND NEW ZEALAND

- ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

- Middle East AND AFRICA: Saudi Arabia, Kuwait, QATAR, Bahrain Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur